Technology is beginning to use its senses

Paraglider robots jump into the abyss like base jumpers, crawler robots search for earthquake victims and sports cars run on electricity. Allow ETH Zurich students to implement their knowledge creatively for a year, and technology becomes exciting and environmentally friendly and begins to use its senses. This is shown by the “Focus Projects 2011” in the ETH Zurich main building.

“Pegasus” and “Paraswift”, “Phoenix” and “Traloc” – the names sound adventurous and daring, but they say one thing above all: the technology of the future is sensuous and attractive. That becomes apparent every year when the Department of Mechanical and Process Engineering presents the students’ “Focus Projects”. And so it was during this year’s presentation on Tuesday afternoon: sponsors, media professionals, curious onlookers and whole families also waited expectantly cheek by jowl with lecturers and students to see what kind of creative designs the mechanical engineers, electrical engineers and industrial designers of the future had dreamt up in the past year.

With the words “This show belongs to the students, not the professors”, Focus Coordinator and ETH Zurich lecturer Roland Haas cleared the stage in the hall of the ETH Zurich main building for the performances by the seventy students divided into seven focus teams. The teams hosted the evening with polished rhetoric and multimedia artistry, showing they had learned not only technical skills but also the art of captivating the public with clever presentations.

Robots as agile as snakes and goats

It is in the nature of their technology that robots captivate visitors at a mere glance: like scarcely any other technical artefact, their typical movements and actions are mirroring more and more the behaviour of living biological creatures. No wonder philosophers are asking whether robots will soon constitute a fourth form of life alongside plants, animals and humans.

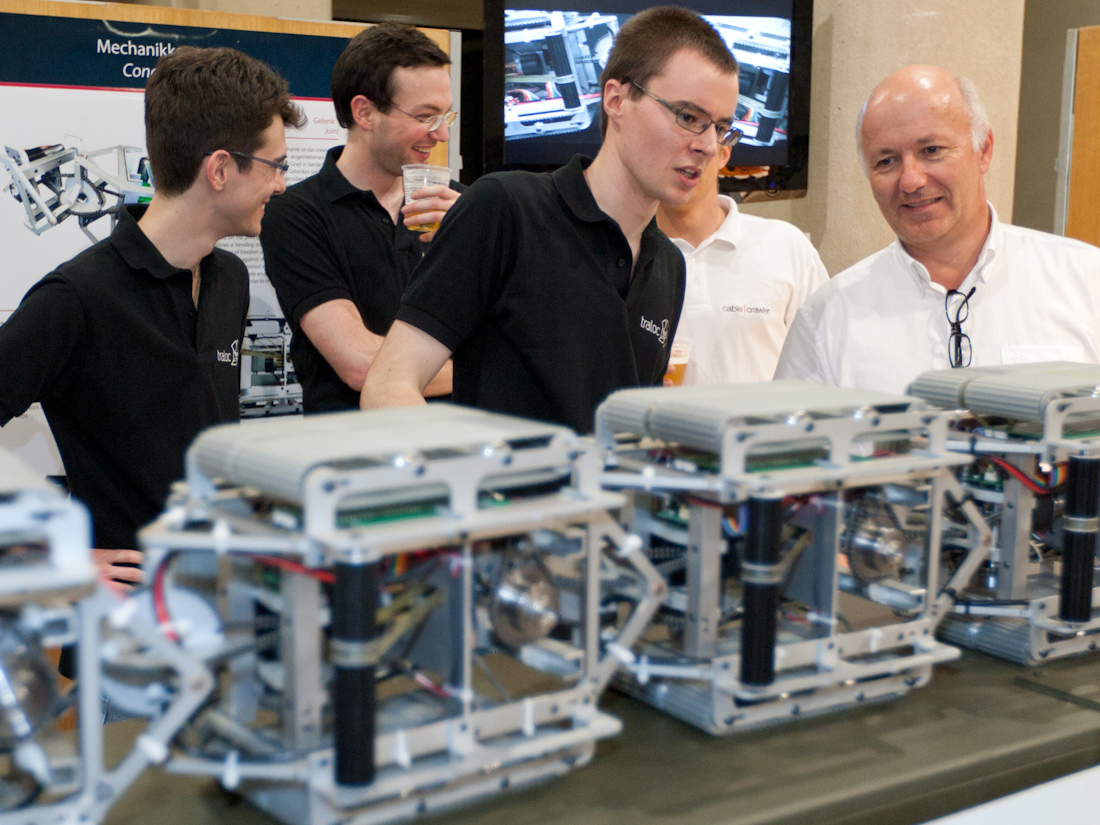

Take “Traloc” for example: it crawls over rubble and debris like a caterpillar, and with its five body segments, four joints and a head-cam it easily overcomes clefts up to half a metre wide and obstacles up to thirty centimetres high even in difficult terrain.

“Traloc” is not alone – there is also “Paraswift”. With its shell-like skin, it looks at first sight like a conch shell. But “Paraswift” does not dive: instead, it expertly climbs up the wall and at the very top it unfurls a paraglider sail that carries it gently down to the ground. Dominik Keusch, a mechanical engineer at the Autonomous Systems Lab of ETH Zurich, admitted that, “in the end time was very short. Our first successful paragliding flight was only two weeks ago.”

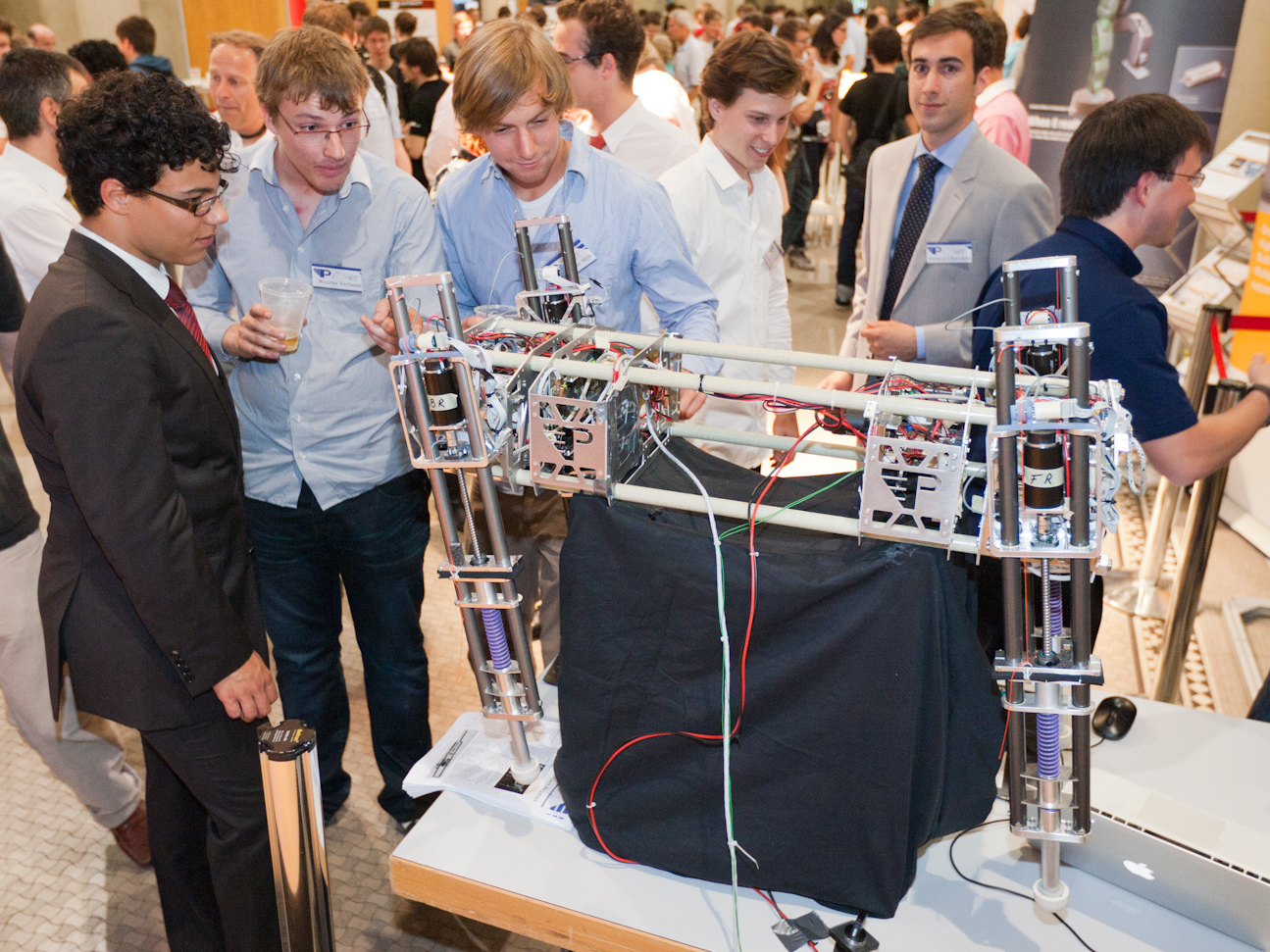

“Pegasus”, which the ETH Zurich students developed together with partners from Delft University of Technology, is inspired by the animal world: this quadruped can trot dynamically like a horse and cushion shocks with its telescopic legs. The team got the idea from a photo showing goats in treetops: team member Maximilian Schulz said “If goats can climb, so can robots.”

The characteristic feature of all three robots is that they assist and support humans: the descendants of “Paraswift” might one day work as mobile searchlights or clean windows on building facades. Future “Tralocs”, for their part, could be tasked with locating victims on earthquake sites. Tobias Bleiker, a seventh-semester electrical engineer and Santiago Droll, a fifth-semester mechanical engineer, explain that, “We observed a rescue exercise in a military training village to best prepare the crawler robot for deployment on such sites.”

Heat flux sensors for the geothermal energy industry

The other “Focus Projects” are characterised by intelligent, environmentally friendly energy and power technologies. The “Heat Flux Sensor” project team developed innovative sensor concepts to measure the flow of heat in geothermal boreholes. To tap into this energy source, experts must drill down to a depth of ten thousand metres through hard rock. For this purpose, ETH Zurich has developed the “Rock Spallation Drilling” technique, which uses a flame at a temperature of 700°C to drill through rock. A more reliable heat flux measurement could markedly reduce the drilling costs.

Sports cars use solar power

The energy-friendly racing cars on the starting grid in the international “Formula Student” engineering competition are the classics among the focus projects. This year the students created the “novena” electrical racing car. Using two high-efficiency three-phase motors (AC motors), “novena” can accelerate from 0 to 100 km/h in 3.2 seconds with zero emissions.

The “SunCar” project team also set itself this challenge. Primarily, however, this team wanted to develop an “environmentally friendly, good-looking” road car powered by solar energy. In around 42,000 hours of work the 32 students replaced the petrol engine of a Lotus with two electric motors. These are supplied with energy by a photovoltaic system and a bio-fuel drive.

The “Phoenix” project also used the 2009 Formula Student racing car as the basis on which to develop a hybrid small car. Because racing engines are not very suited to normal highway conditions, the students designed a hybrid-electric drive train appropriate for everyday use. If their simulations are correct, “Phoenix” could reduce fuel consumption by one third.

The innovative spirit lasts a lifetime

A sponsor awarded the “Traloc” team the prize for the best application of a CAD environment. Delighted electrical engineer Tobias Bleiker and mechanical engineer Jérôme Darbre said, “We find that enormously satisfying. The cool aspect of the project was that we were able to exchange our ideas and expert knowledge constantly within the team, and to apply them under real working conditions.”

For Roland Siegwart, Vice President Research and Corporate Relations, the value of the “Focus Projects” lies in such learning processes: “The students work to a timetable in a company, so to speak, and this teaches them teamwork and management skills. The benefit to industry and society is the innovative spirit they acquire in so doing.”

Focus Projects: practice-oriented learning

In the Focus Projects at the Department of Mechanical and Process Engineering, ETH Zurich mechanical engineering students learn the practical application of their theoretical knowledge. During two semesters, supported by students at various Universities of Applied Sciences, they develop a product independently. Starting from an innovative product idea, this involves the teams passing through all the processes of product development: marketing, conceptualisation, design, engineering, simulation, drafting and production.

READER COMMENTS